Construction & Building Products Supplier

/

Rubber Gate Seals

/

Bulb and Tail

/

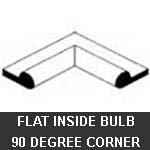

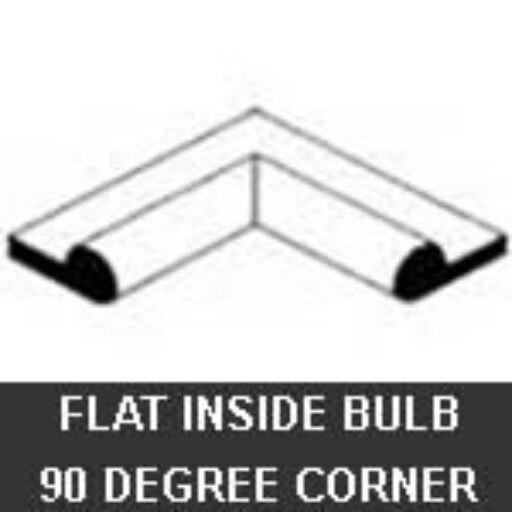

Flat Inside Bulb 90 Degree Corner

/

Flat Inside Bulb 90 Degree Corner-Natural 1187

/

FIB90DC-N1187-2-1/4″ x 6″ x 9/16″ x 10″ x 5/16″

Categories

Categories

Construction & Building Products Supplier

/

Rubber Gate Seals

/

Bulb and Tail

/

Flat Inside Bulb 90 Degree Corner

/

Flat Inside Bulb 90 Degree Corner-Natural 1187

/

FIB90DC-N1187-2-1/4″ x 6″ x 9/16″ x 10″ x 5/16″

FIB90DC-N1187-2-1/4" x 6" x 9/16" x 10" x 5/16"

Product Code: FIB90DC-N1187-2250-6000-05625-10000-03125

You must be logged in.

Options

FIB90DC-N1187-0875-3000-03125-7000-0125

FIB90DC-N1187-1000-5000-0500-11000-04375

FIB90DC-N1187-1000-6000-03125-10000-0375

FIB90DC-N1187-1250-6000-0500-10000-01875

FIB90DC-N1187-1500-6000-0500-10000-0250

FIB90DC-N1187-1750-7000-05625-11000-03125

FIB90DC-N1187-1750-7000-06875-10000-03125

FIB90DC-N1187-1750-7000-0750-10000-03125

FIB90DC-N1187-1750-7000-0875-10000-03125

FIB90DC-N1187-2000-7000-0875-10000-01875

FIB90DC-N1187-2000-7000-1000-10000-0250

FIB90DC-N1187-2250-6000-05625-10000-03125

FIB90DC-N1187-2250-6000-0750-10000-03125

FIB90DC-N1187-2250-7000-1000-11000-0250

FIB90DC-N1187-2375-7000-1000-11000-0250

FIB90DC-N1187-2500-6000-0875-11000-0375

FIB90DC-N1187-2750-6000-1000-10000-0375

FIB90DC-N1187-3000-7000-1000-11000-04375

Description

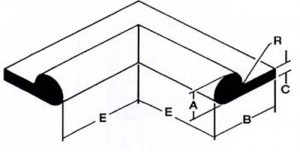

Drawing Item Identification:

A: Bulb in inches

B: OA width in inches

C: Tail thickness in inches

D: Optional customer specified hole if needed

E. Side length in inches

R: Radius in inches

Additional information

| (A) Bulb in inches | 2-1/4" |

|---|---|

| (B) OA Width in Inches | 6" |

| (C) Tail Thickness in Inches | 9/16" |

| (D) Optional Customer Specified Hole if Needed | – |

| (E) Side Length in Inches | 10" |

| (R) Radius in Inches | 5/16" |

| Tensile Strength (Die C ASTM D412) | 2500 psi (min) |

| Elongation at Rupture (ASTM D412) | 400% (min) |

| 300% Modulus (ASTM D412) | – |

| Durometer Hardness, Shore Type A (ASTM D2240) | 50 – 60 |

| Water Absorption (70 Hrs. @ 212°F ASTM D471) | 10% by volume (max) |

| Compression Set (ASTM D395 Method B 22 Hrs/ @ 158°F) | 25% (max) |

| Tensile Strength After Oxygen Bomb Aging (ASTM F572) | – |

| Low Temperature Brittleness (ASTM D2137 Method A, 9.3.2) | Non-Brittle after 3' @ -40°C |