Categories

Categories

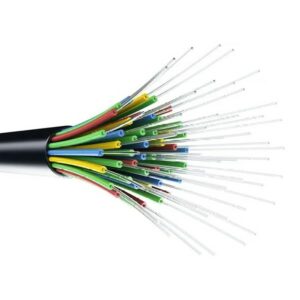

Industrial Tubing Supplier

Hanna Rubber Company is a manufacturer and stocking distributor of plastic and rubber tubing.

Our tubing is available in a wide variety of materials including PVC, latex, nylon, NSF, polyethylene, polypropylene, TPR and many more. We specialize in custom manufacturing and will produce small runs to your specific requirements.

Don't see what you are looking for?