Categories

Categories

Norseal

Product Code: NORSEAL

You must be logged in.

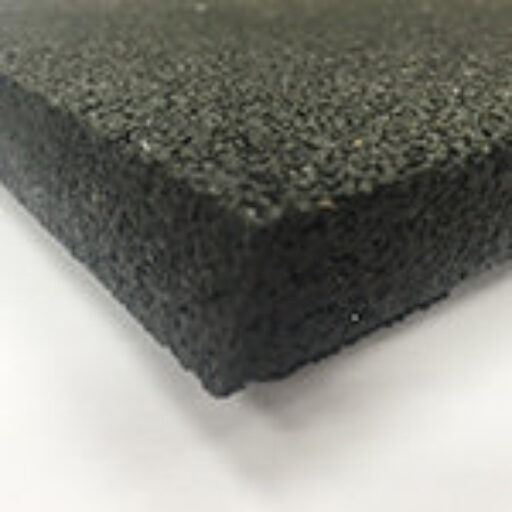

Description

Typical Physical Properties

| Property | Standard | Unit | Value |

| Thickness | in | .24 – .35 – .51 | |

| (mm) | (6.0 – 9.0 – 13.0) | ||

| Density | ASTM D1056 | kg/m³ | 240 |

| Force to Compress | ASTM D1667 | psi | |

| @20% | 13 – 36 | ||

| @40% | 43.5 – 101.5 | ||

| @60% | 119 – 232 | ||

| Compress Force Deflection | ASTM D1667 | psi | |

| @20% | 5.8 – 16 | ||

| @40% | 17.5 – 43.5 | ||

| @60% | 49.5 – 104.5 | ||

| Tensile Strength | ASTM D412A | psi | 26 – 32 |

| Elongation at Break | ASTM D412A | % | 85 – 120 |

| Compression Set @15 days at 50% at 23°C | ASTM D1667 | % | 5 |

| Combustion ASTM 4986 | ASTM 4986 | Classification | VO |

| Limit Oxygen index | ISO 4589-2 | 27.5 | |

| EU Small Flame Test | ISO 11925-2 | Equivalent classification | B |

| Expansion Ratio | PRT129 | % | 200 |

| Temperature of Activation | PRT130 | C | 200 |

| Heat Conductivity | Internal | W/.K | 0.039 |

| Water Tightness | 30% Compression | Hours before leakage | >72 |

| NTP 38 | |||

| Air Tightness | 1000 Pa | Air leakage in ml/m/min | 0 |

| 30% Compression | |||

| PRT128 |