Categories

Categories

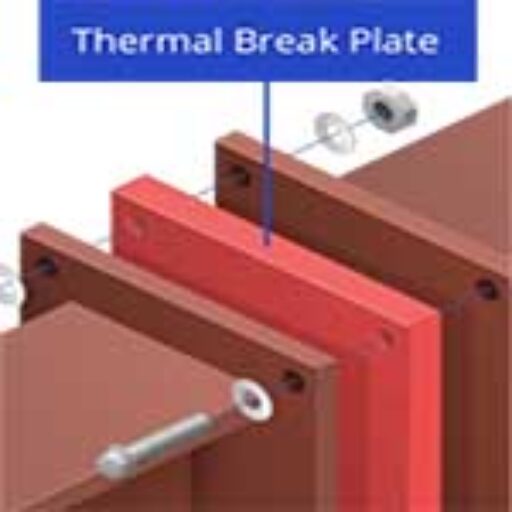

Thermal Break Material

Thermal Break Material is ideal to prevent thermal bridging in structural links, it is used between flanged connections of internal and external steelwork and concrete to prevent thermal/ cold bridging.

| Properties | Procedure | Value |

|---|---|---|

| Colors | Black | |

| Max Service Temp | 550° F (288° C) | |

| Continuous Use Temp | 412° F (211° C) | |

| Flexural Strength | ASTM D790 | 31,000 psi |

| Tensile | ASTM D638 | >11,000 psi |

| Compressive Strength@ 75° F | ASTM D695 | 49,000 psi |

| Compressive Modulus | ASTM D695 | 1,800,000 psi |

| IZO Impact Strength | ASTM D256 | 8 Ft. lb./in. |

| Flexural / Bending Strength | ASTM D790 | 29,000 psi |

| Water Absorption | ASTM D570 | 0.2% by weight |

| Specific Gravity | ASTM D792 | 123 lbs/ft (cubed) |

| Thickness Tolerance | ±0.002 inches | |

| Coefficient of Thermal Expansion: | ||

| -across thickness | ASTM D696 | 11.62 In/In/°Cx10-5 |

| -across surface | ASTM D696 | 2.21 In/In/°Cx10-5 |

| Thermal Conductivity | ASTM C177 | Ca. 0.30 W/mx°K |

| Flame Retardant Properties | UL 94 | V0 |