Categories

Categories

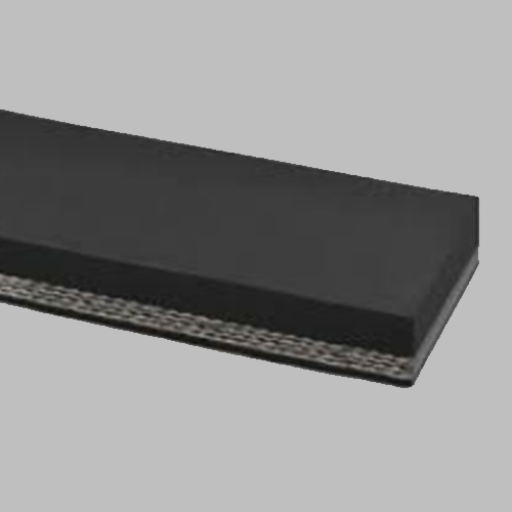

EPDM Peroxide Cure 60

Product Code: EPDM-PEROXIDE-CURE-60

You must be logged in.

Additional information

| Duro | 60 |

|---|---|

| Thickness (in.) | 1/64 – 1/4 |

| Width (in.) | 36, 48 |

| Tensile Strength Psi | 1800 |

| Ultimate Elongation Percent | 350 |

| Temp Range | -55°F to +300°F |

| Weight | 6.45 |

| Specifications | 4CA 615 A25 B35 C32 EA14 F21 |